What is Eddy Current testing?

- Eddy Current testing is the use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials

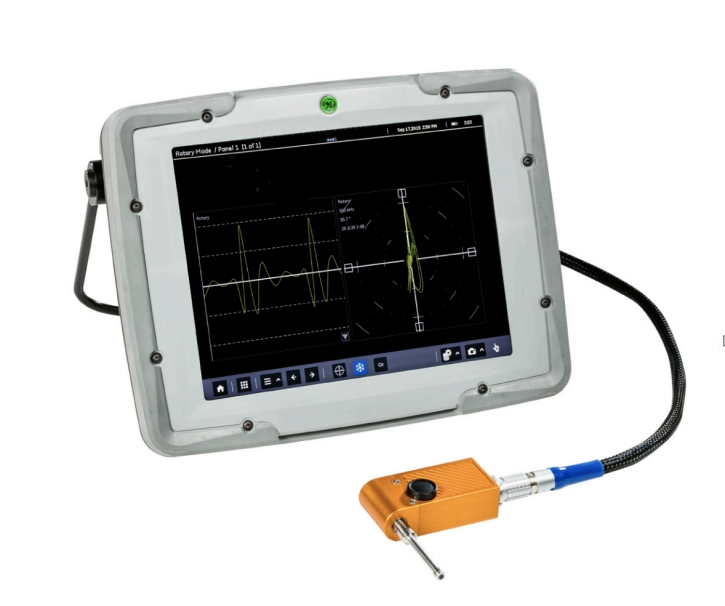

- Eddy current sensors sense displacement and are formed when a changing magnetic field intersects a conductor

- Probes sense the change and find out the distance between the probe and the test material

- Electric current is induced into the test subject and the change in the current is noticed and determines a fault. There will be a corresponding change in the phase and amplitude of the signal that is measured.

- Eddy Current can measure metal thickness so erosion or metal thinning can be detected

- Eddy current is one of six methods of NDT testing: eddy current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, visual testing

Advantages of Eddy Current Testing

- Faster scanning speed than ultrasonic testing

- Minimal preparation for surfaces to be tested

- EC can test through several millimeters of coating

- Very sensitive - can detect very small cracks

- Testing devices are portable with immediate results/feedback

- The test equipment does not need to be in direct contact with the item being tested

- Production is not interrupted due to fast and automated testing

- Groups of sensors can be used to provide a larger area scan

Eddy Current Applications

- Aerospace Industry

- Petrochemical Industry

- Material sorting- used to determine that the proper materials are being used for a job

- Used to determine material characteristics/purity of the metal

- Tube and wire testing

- Weld testing

- Coating thickness measurement