Magnetic Particle Testing (MPT)

Magnetic particle inspection acc. to DIN EN ISO 9934

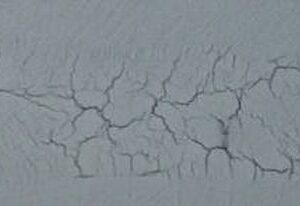

Magnetic particle inspection is suitable for detecting discontinuities (e.g. cracks) in or near the surface of ferromagnetic materials.

The workpiece must be magnetized in the test area. The discontinuity can be shown best if the magnetic field is vertical to the discontinuity. One possible method for magnetization is using a yoke. The magnetic flux flows into the workpiece through a ferromagnetic yoke. The main field direction is the connection line between the two poles of the yoke. Yokes can be installed in a test bench so that the whole material can be magnetized. If hand yokes are used only the region between the two poles can be magnetized. Multi-directional magnetization can be used to find discontinuities in any direction.

Detection media

There are various types of detection media: a suspension of coloured (including black) or fluorescent particles in a carrier fluid (based on water or oil), or dry powders. Fluorescent media usually gives the highest sensitiviy.

Dry testing:

The test area can be sprayed with a dry magnetic powder, or the workpiece can be dipped into a container in which the particles are kept afloat by air whirling (eddy pot procedure). The dry testing is recommendable where a wetting of the surface must be avoided, or with the examination of hot parts.

Wet testing:

The magnetic powder is suspended in a carrier fluid. The particle size of the powder is smaller so that smaller discontinuities may be detected.

Process descriptions